Video Pipe Inspection Services

Detect Leaks, Cracks, and Blocks.

Video Pipe Inspection is a safe and non-destructive way to detect pipes' leaks, cracks, and blocks.

Video Pipe Inspection Services

WE FIND BREAKS, DEFECTS & CROSS BORES.

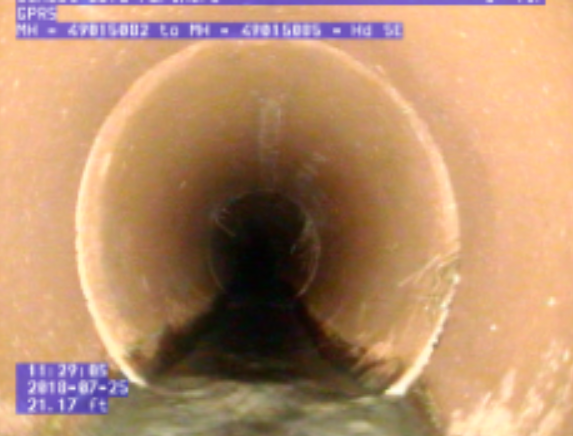

Video Pipe Inspection (CCTV) is a sewer inspection service that uses industry-leading remote video cameras to assess conditions and prevent problems in water, sanitary and storm sewer, and lateral pipelines.

It can be very time-consuming and expensive to excavate and examine lines to find a blockage, a crack, or other problem. Since cameras can navigate through underground pipes, they can detect damage within areas that cannot typically be viewed through visual inspection. Sewer mains and lateral lines can be inspected with video equipment extending hundreds of feet. Our NASSCO-certified Project Managers scope your sewers to locate clogs, identify cross bores, find structural defects & damages, and conduct lateral sewer line inspections. GPRS provides comprehensive, detailed reporting for every single inch of your pipes, taking the surprise out of the subsurface, one section of pipe at a time.

Video Pipe Inspection Serves Two Primary Purposes:

- Location & Analysis

Locating a pipe is crucial for excavation safety, but inaccurate or outdated data can make pipes challenging to find. When detecting pipe complications, infrastructure analysis provides accurate location data for underlying faults that must be fixed.

- Location of Sewer, Storm, and Drain Pipes

Sometimes video pipe inspection is the only option. Plus, video pipe inspection is largely non-destructive and is the smartest way to map and investigate pipelines to locate and catalogue defects.

Location of Sewer, Storm, and Drain Pipes

Location of Pipes

To complete a safe excavation, it is essential to identify the location of subsurface pipe infrastructure. While traditional utility locating methods are excellent in many ways, there are other circumstances when video pipe inspection is the only option.

Analysis of Pipes

An underground sewer line or lateral pipeline can be inspected with VPI. Inspections of lateral sewer lines by VPI technicians can uncover structural damage, discover cross-bores, and locate clogs.

Video pipe inspections are one of the most valuable diagnostic methods because they are non-destructive. By using VPI, you can detect holes, leaks, obstructions, and more, including:

Misalignment, termination, and vaults

Cross bores caused by directional drilling

Unidentified storm laterals and sanitary lines

Infrastructure weaknesses

Grease accumulations and clogs

Breaks, punctures, and corrosion

Utility lines: their location, grade, and depth

An inspection can also verify cleaning and repairs after they have been completed. Video pipe inspections can be used as an accountability measure as well. Contractors sometimes use VPI to assess pipe conditions before and after completing a project.

Video Pipe Inspection Tools

GPRS has the tools to get the job done. Investing in innovation means we have the finest tech on the market. Your pipelines are carefully mapped, with your data being available in our cutting-edge platform- SiteMap®. In SiteMap®, you’re able to interact with your data like never before, navigating through detailed, aggregated, customizable maps on any device, from anywhere.

Mainline Crawler

All GPRS Project Managers are experts in utilizing CCTV cameras to investigate sanitary and storm sewers as part of our Video Pipe Inspection Services. Mainline crawlers and their small-diameter crawler cousins are used in concert with push cameras, EM locators, and other technology to provide accurate, comprehensive subsurface visualization and NASSCO-certified reporting.

Push Cameras

Push cameras, also called flexible rodders, can access pipes through smaller spaces than crawlers. These spaces include things like vents, cleanouts, and toilet plumbing. The push camera contains a sonde that can also be detected by a properly programmed EM locator to map non-metallic pipes as part of a full site utility scan or NASSCO VPI report. Cameras are routinely used for sewer lateral inspections for pipes ranging from 2"- 6". These cameras can:

Inspect interior sewer laterals and drains under buildings with high-resolution video cameras.

Expand the range of the camera up to 300 feet.

Robotic CCTV Crawlers

Inspecting pipes (usually sewers and drains) 6" to 96" in diameter is possible due to VPI robotic CCTV crawlers. An inspection of the pipeline with CCTV can provide details and identify infractions, cracks, and other imperfections. They can also locate the lines. Featuring 360-degree pan and tilt capability and zero-degree turning capability, the CCTV camera offers excellent adaptability and visibility for this application. Crawler cameras can:

- Move 1000LF from its insertion point

- Track pipe grade

- Relay real-time video to a NASSCO-certified project manager via remote control

- Measure the pipe for defects and ovality.

Lateral Launch Cameras

The lateral launch is a type of robotic crawler used for CCTV pipe inspection. You can inspect laterals from the mainline with this sewer inspection video system. This service is commonly used to inspect cross bore pipes and mitigate cross bore problems. For the inspection of mainline and lateral sewer pipes, these lateral launch systems feature a variety of features. For example:

- The ability to crawl at least 150' into laterals up to 2" in diameter, and 1000' into pipes at least 6" in diameter.

- 360-degree pan and 90-degree tilt capability of the auto-leveling camera allows a comprehensive view of the pipeline.

- Navigation through the pipe is more accessible with a steering 6-wheel drive and a rear-view camera.

- The SIM program requires VPI technicians to be familiar with these and other advanced technologies.

EM Locator

Electromagnetic (EM) locators are the tools preferred by One Call contractors to locate public utility lines. GPRS utilizes EM devices in concert with GPR and our VPI technologies as part of our Subsurface Investigation Methodology (SIM) process to passively detect live AC power or radio signals that travel along conductive utilities. It can also be used to find accessible metallic pipes, risers, or tracer wires.

GPRS uses lateral launch cameras as part of a video pipe (CCTV) inspection and/or a full-site utility locate to non-destructively investigate lateral storm and sanitary sewer lines upstream of a mainline to find pipe defects, cross bores, abandoned pipes, and effectively map a sewer system.

The lateral launch is a type of robotic crawler used for CCTV pipe inspection. You can inspect laterals from the mainline with this sewer inspection video system. This service is commonly used to inspect cross bore pipes and mitigate cross bore problems. For the inspection of mainline and lateral sewer pipes, these lateral launch systems feature a variety of features. For example:

- The ability to crawl at least 150' into laterals up to 2" in diameter, and 1000' into pipes at least 6" in diameter

- 360-degree pan and 90-degree tilt capability of the auto-leveling camera allows a comprehensive view of the pipeline

- Navigation through the pipe is more accessible with a steering 6-wheel drive and a rear-view camera

Subsurface Investigation Methodology (SIM) requires VPI technicians to be experts with these and other advanced technologies.

Qualifications & Certifications

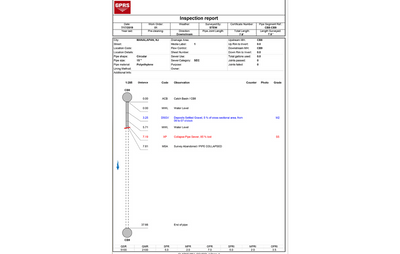

Our pipe inspection reports are NASSCO-compliant.

The National Association of Sewer Service Companies is NASSCO. In addition to assessing, maintaining, and rehabilitating underground infrastructure, NASSCO sets standards for the industry. Our Project Managers are certified by NASSCO, and our pipe inspection reports are NASSCO-compliant. NASSCO offers three types of training and certification. The three certification programs are: pipeline assessment, lateral assessment, and manhole assessment. These programs are referred to as PACP, LACP, and MACP.

GPRS VPI Project Managers are trained and certified through the PACP to assess pipelines, manholes, and laterals. LACP courses teach technicians how to deal with the fittings and access points specific to laterals. Through MACP training, a process is established for documenting all defects, examining the condition of the manhole, and providing detailed information required to identify any necessary corrective actions.

SIM provides GPRS with a video pipe inspection standard that emphasizes training and repeatability. Subsurface Investigation Methodology is a rigorous and thorough specification to prevent subsurface damage.

INSPECTION PROGRAMS

GPRS offers two primary inspection programs to help keep your pipes flowing freely:

Routine Sewer Inspection

GPRS strongly recommends periodic sewer system inspections every other year to update your existing condition documentation, find new breaks, cross bores, and defects, and protect your system, facility, and community.

- Video Pipe Inspection of Sanitary or Storm Sewer Systems

- Reduces/Eliminates Service Interruptions, Contamination Incidents & Damages

- Pipe Defects Ranked by Severity in a WinCan Interactive, NASSCO-Certified Report

- Recommended Every Two Years for Large Facilities, Campuses & Municipalities

Pre & Post-Cross Bore Inspections

We also recommend cross bore inspections that assess pipe locations and conditions prior to the deployment of trenchless technology, and immediately following the installation of any new utilities via trenchless technology, to mitigate the risk of cross bores and the dangers they pose.

- Contractors Required to Conduct a VPI Inspection Before Utilizing Trenchless Technology

- Provides a Baseline for Sewer As Built Information Before Applying Trenchless Technology

- Re-Inspection Required Immediately After Applying Trenchless Technology

- Mitigates Risk, Damage, And Potential Liability for Your Facility, Campus, or Municipality

Routine Sewer Inspection

- GPRS strongly recommends periodic sewer system inspections every other year to update your existing condition documentation, find new breaks, cross bores, and defects, and protect your system, facility, and community.

- Video Pipe Inspection of Sanitary or Storm Sewer Systems

- Reduces/Eliminates Service Interruptions, Contamination Incidents & Damages

- Pipe Defects Ranked by Severity in a WinCan Interactive, NASSCO-Certified Report

- Recommended Every Two Years for Large Facilities, Campuses & Municipalities

Pre & Post-Cross Bore Inspections

We also recommend cross bore inspections that assess pipe locations and conditions prior to the deployment of trenchless technology, and immediately following the installation of any new utilities via trenchless technology, to mitigate the risk of cross bores and the dangers they pose.

- Contractors Required to Conduct a VPI Inspection Before Utilizing Trenchless Technology

- Provides a Baseline for Sewer As Built Information Before Applying Trenchless Technology

- Re-Inspection Required Immediately After Applying Trenchless Technology

- Mitigates Risk, Damage, And Potential Liability for Your Facility, Campus, or Municipality

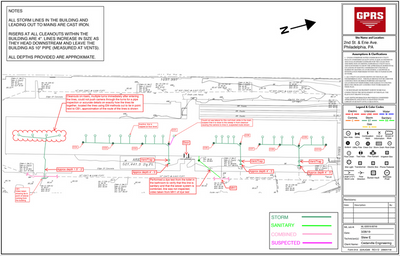

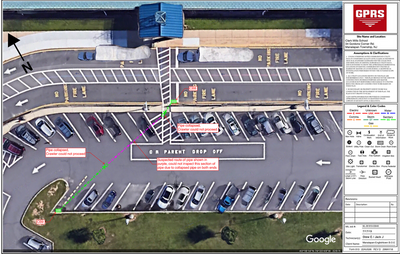

Water & Sewer System Mapping

GPRS VPI services enhance a utility locate or full-site scan because we not only find the pipes, we deploy robotic sewer scope cameras, push cameras, lateral launch cameras, and additional technologies to inspect them, document their existing conditions in an interactive, NASSCO-certified report, and include them in a comprehensive, layered utility map, delivered digitally via SiteMap® for your use, 24/7.

NASSCO Reporting

All GPRS VPI Project Managers are NASSCO-certified in PACP, LACP, and MACP, along with our required Subsurface Investigation Methodology (SIM) certification. This makes our Project Managers experts in locating, identifying and mapping complex sewer systems, and categorizing pipe defects to provide comprehensive reporting.

GPRS employs WinCan software in concert with our sewer scope technologies to provide interactive, NASSCO-certified existing condition reporting. GPRS reports everything you need to get the full picture. These reports include photos and video of each pipe defect, mapped and categorized by type and severity to provide a complete sewer system overview, so that you can repair, maintain, and plan effectively

Utility Locating

On average, 65% off all utility lines and sewer pipes are privately owned.

Your state’s One Call (811) system is an effective and outstanding tool that is responsible for marking all public utility lines. However, they will not mark privately owned lines, and do not provide depths on the public lines they do mark. A comprehensive utility locate that accurately captures both public and private lines is the only way to be sure you won’t suffer a dangerous and expensive utility strike when you drill or dig. GPRS boasts a 99.8% accuracy rating across more than 400,000 jobs nationwide!

GPRS can locate all private and public utilities, including depths, and provides state-of-the art field markings, complimentary PDF and .KMZ files, and a digitized, layered utility map of your site delivered via SiteMap® – our proprietary project & facility management software application that’s accessible to GPRS customers 24/7.

Leave the surprise out of the subsurface, contact GPRS today to learn more about the exciting ways you can interact with your utility lines.

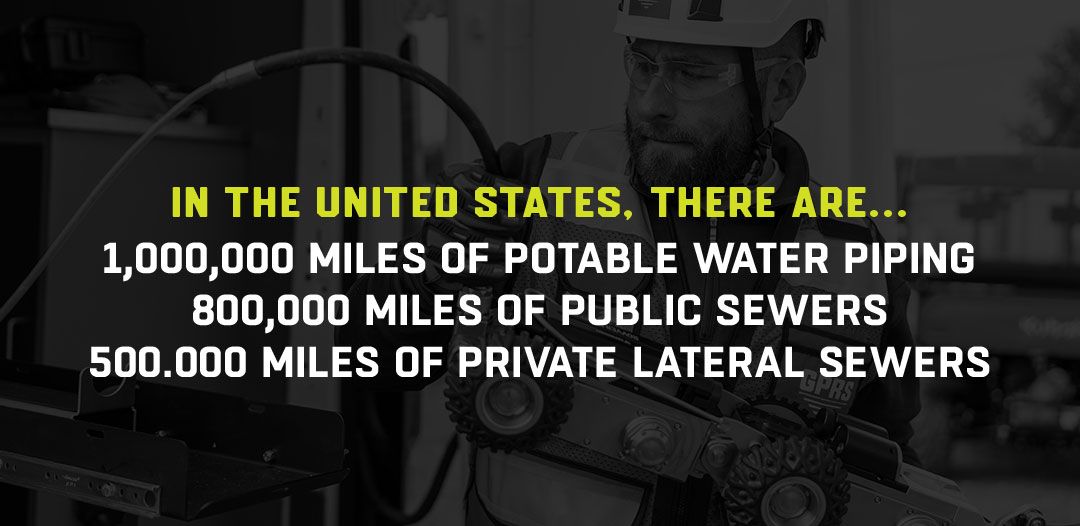

GPRS is there to monitor them all. GPRS offers a variety of services for pipe inspection, locating, and mapping, including:

The National Association of Sewer Service Companies is NASSCO. In addition to assessing, maintaining, and rehabilitating underground infrastructure, NASSCO sets standards for the industry. Our Project Managers are certified by NASSCO, and our pipe inspection reports are NASSCO-compliant. NASSCO offers three types of training and certification. The three certification programs are: pipeline assessment, lateral assessment, and manhole assessment. These programs are referred to as PACP, LACP, and MACP.

GPRS VPI Project Managers are trained and certified through the PACP to assess pipelines, manholes, and laterals. LACP courses teach technicians how to deal with the fittings and access points specific to laterals. Through MACP training, a process is established for documenting all defects, examining the condition of the manhole, and providing detailed information required to identify any necessary corrective actions.

SIM provides GPRS with a video pipe inspection standard that emphasizes training and repeatability. Subsurface Investigation Methodology is a rigorous and thorough specification to prevent subsurface damage.

The National Association of Sewer Service Companies is NASSCO. In addition to assessing, maintaining, and rehabilitating underground infrastructure, NASSCO sets standards for the industry. Our Project Managers are certified by NASSCO, and our pipe inspection reports are NASSCO-compliant. NASSCO offers three types of training and certification. The three certification programs are: pipeline assessment, lateral assessment, and manhole assessment. These programs are referred to as PACP, LACP, and MACP.

GPRS VPI Project Managers are trained and certified through the PACP to assess pipelines, manholes, and laterals. LACP courses teach technicians how to deal with the fittings and access points specific to laterals. Through MACP training, a process is established for documenting all defects, examining the condition of the manhole, and providing detailed information required to identify any necessary corrective actions.

SIM provides GPRS with a video pipe inspection standard that emphasizes training and repeatability. Subsurface Investigation Methodology is a rigorous and thorough specification to prevent subsurface damage.

Sample Reports

- Push Cam - Rigid SeeSnake Micro Reel - 1.5" to 4" Lines, 100' Cable Length, Built in 512 Hz Sonde

- Push Cam - Rigid SeeSnake - 2" to 12" Lines, 325' Cable Length, Built in 512 Hz Sonde for Pin Pointing Defects Above Ground

- Push Cam - Verisights - 2" to 12" Lines, 200' Cable Length, Built in 33 KHz, 512 Hz, 640 Hz for Locating

- Lateral Launch (in certain markets)

- Robotic Crawler

Case Studies

Buckley School Storm Sewer Locate And Video

GPRS was contacted by a local contractor in Southern California that had a problem that needed solving. They had a project at the Buckley School in Sherman Oaks, and they needed to determine where the main storm sewer line was running along with the location of any taps in the work area(s). This might seem like a pretty simple project, however, the storm sewer pipe is a 51 inch RCP (Reinforced Concrete Pipe) and it is roughly 20-25 feet deep.

Residential CCTV Pre & Post Inspections

Many cities and counties around the US have started requiring pre and post inspections of storm and sanitary sewer lines if any work is taking place near those utilities. GPRS was called out to a residential build, where a swimming pool was being constructed near the city sanitary sewer line. The purpose for the pre and post inspections is to determine if there was any change in the pipe condition before and after the construction takes place.

Schedule a Project Today

GPRS specializes in ground penetrating radar, video pipe inspection, and mapping and modeling services. Our Project Managers have the equipment and expertise to handle all subsurface challenges presented. GPRS does this by utilizing various equipment paired with their industry-leading SIM process.

Don't wait. To schedule a project with GPRS, click here. Our highly trained Project Managers will keep your project on time, on budget, and safe.