Unlocking Subsurface Clarity: How GPRS’ SiteMap Sewer Layer Helps Facilities Managers Locate and Assess Underground Pipes

New In-App Video and Data Offers Real-Time Insight into Pipe Conditions and Defects

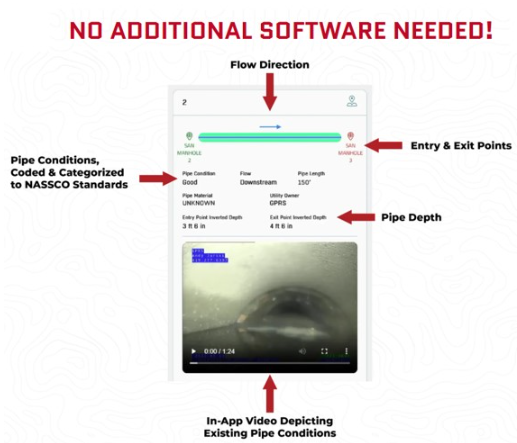

A comprehensive report of pipe conditions, catalogued to NASSCO standards, includes flow direction, depth, and video of each pipe segment.

Facilities managers know the headaches that come with managing wastewater systems. Now, a new tool from GPRS is making that job easier by providing 24/7 access to detailed subsurface sewer data. The SiteMap® Sewer Layer allows users to visualize their sanitary and storm sewer infrastructure with precision, no matter where they are.

Historically, locating and maintaining underground sewer lines has involved relying on outdated or incomplete as-builts, digging blindly through potholing, and spending time and money trying to identify the source of a blockage or overflow. Even after all that effort, managers often still lack a clear picture of where their pipes, cleanouts, and laterals are located. Cross bores caused by trenchless installations can go undetected, leading to serious damage.

GPRS developed the SiteMap Sewer Layer to address these challenges. It provides accurate, centralized sewer mapping data that supports daily operations, long-term planning, and risk reduction. Facilities and municipal managers now have a reliable way to manage their wastewater infrastructure with confidence.

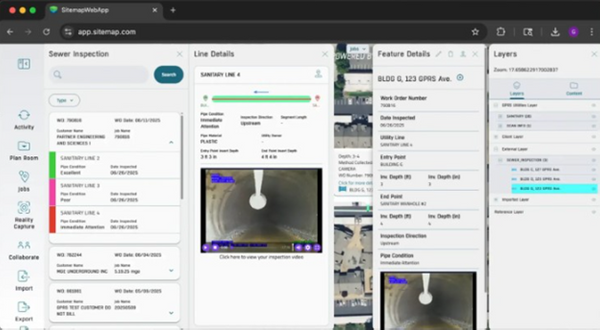

Municipal & Facilities Managers can see all of their sanitary and storm sewer data in a single click, and securely access and share it via SiteMap.

What Is the SiteMap Sewer Layer?

The SiteMap Sewer Layer is built on advanced video pipe inspection tools, including robotic crawler cameras and lateral launch push cameras. These systems work alongside utility locating technologies such as ground penetrating radar (GPR), electromagnetic locators, tracer wires, and sondes to collect high-resolution imagery and video. This data is used to assess pipe conditions and map sewer lines, laterals, and manholes with precision.

Once collected, the data is uploaded to the SiteMap® platform (patent pending), where it can be viewed, analyzed, and shared in real time. No extra software is needed to access geolocated pipe segments, entry and exit points, material type, depth, flow direction, and condition: all coded to NASSCO standards. The platform also includes in-app video of each segment, allowing facilities teams to plan, maintain, and upgrade their systems with confidence.

This proactive approach helps:

• Minimize potholing and unnecessary excavation

• Prevent utility strikes and service disruptions

• Detect cross bores before they cause serious damage

GPRS Chief Strategy Officer Jason Schaff explained the value of this innovation in a recent press release:

“Two of the biggest problems we’ve been trying to tackle for our customers, especially those managing large campuses or municipalities, are how we can give them concrete evidence showing them exactly where in the world their sewer lines are, and what condition they are in, so that they have access to that data in the palm of their hand 24/7.”

“We believe SiteMap’s Sewer Layer update solves both issues; not only can you see direct video of every pipe segment and its condition, each line is geolocated with real-time kinematic positioning (RTK), so you can be certain of the location of every pipe in your wastewater infrastructure. And since it’s all delivered via SiteMap, you have complete access and control of your wastewater system data from anywhere, anytime you need it, to plan upgrades, expansions, and repairs.”

How Does It Help Facilities Managers?

Facilities managers across industries, from education and healthcare to manufacturing and municipal services, can use SiteMap to shift from reactive to proactive maintenance. It supports capital planning, reduces service interruptions, and helps locate undocumented sewer lines that could otherwise delay construction.

On university campuses, where sewer systems may span centuries, SiteMap helps identify issues like root intrusion or pipe deformation before they become emergencies. The University of Toledo now has its entire subsurface infrastructure, including sanitary and storm sewers, water lines, and steam systems, mapped and cataloged in SiteMap.

In manufacturing, sewer failures can halt production and pose safety risks. SiteMap gives plant engineers visibility into critical lines beneath production floors and hazardous areas. A Midwest automotive manufacturer used SiteMap to scan 3.7 million square feet across 419 acres during a major renovation.

“One of the biggest issues we were solving [for the auto plant] was scanning and collecting the data proactively ahead of the project rather than waiting until the construction phase. This gave them the subsurface information they needed to design and plan with accurate information that we updated from the out of date and inaccurate as builts.” – Nate Stair, GPRS SiteMap Market Segment Leader & Account Executive

Municipal wastewater departments benefit from SiteMap’s ability to unify data across teams and locations. With aging infrastructure and tight budgets, accurate condition assessments are essential. The City of Fremont, California used GPRS’ video pipe inspection and SiteMap to locate and remediate 10 hazardous cross bores caused by fiber line installations. Cloud-based access enabled seamless collaboration between public works, engineers, and contractors.

Across the country, municipalities are adopting pre- and post-installation cross bore inspections to prevent sewer damage from utility intrusions.

Hospitals and medical campuses also gain critical visibility. General contractor Rudolph Libbe used SiteMap to trace century-old sewer lines and verify subsurface infrastructure before building a new central utility plant at Mercy Health’s St. Vincent Medical Center. With accurate mapping and video documentation, the team was able to position the CUP closer to the hospital than typically possible, thanks to reliable subsurface data.

What Are the Benefits of SiteMap’s Sewer Layer?

SiteMap’s Sewer Layer offers:

• Navigation to any line, lateral, or feature in your sewer system

• On-demand access to geolocated, annotated pipe condition videos

• Filtering by defect level and pipe condition

• Secure sharing with internal teams and external partners

• A permanent record for future planning and maintenance

The bottom line: GPRS’ new SiteMap Sewer Layer gives facilities managers a powerful tool for reducing risk, optimizing maintenance, and extending the life of critical wastewater infrastructure.

What can we help you visualize? Schedule your personal SiteMap demonstration and view information about the new Sewer Layer, here.