Concrete Coring Explained: How it’s Performed and How GPRS’ Services Help GCs Core Safely

GPRS’ 99.8% Accuracy Rate when Scanning Concrete Provides the Information Needed to Avoid Disaster

Concrete coring can be utilized to create access for new systems, validate material properties, or support structural work.

What Is Concrete Coring?

Concrete coring is the controlled, precise drilling of circular holes into concrete structures.

The task appears straightforward. However, successful coring requires disciplined planning, the right equipment, and reliable subsurface data that shows what is embedded in or beneath the slab before breaking ground.

Coring starts with selecting the proper drill and core bit diameter to match the specified conditions. Diamond core bits are preferred by general contractors because they cut through concrete with limited vibration and reduced dust. The drill is fixed to a handheld or anchored rig to maintain stability.

To keep the bit cool and suppress dust, water is typically applied to the concrete during coring. In sensitive environments, including healthcare and data facilities, dry coring can be deployed with vacuum systems to lessen the effects of dust and debris.

The operator must maintain consistent pressure and track their progress to avoid damaging the surrounding slab, embedded utilities, or structural reinforcements.

Cores can be extracted and tested to determine compressive strength, density, and other performance considerations.

Why Is Concrete Coring Necessary?

Concrete coring supports multiple workflows across industries:

Utility Installation: Creating pathways for electrical conduit, plumbing, or ductwork through concrete walls and floors for electricians, plumbers, and HVAC techs

Structural Testing: Obtaining core samples to assess in-place concrete quality and integrity in existing structures for engineers

Retrofitting and Renovation: Adding new systems or openings during upgrades without undermining load paths or serviceability

Anchoring and Fastening: Installing anchor bolts, dowels, or other structural connections that must meet design tolerances

Precision is critical. Misplaced or poorly executed cores can damage infrastructure, increase rework, and create safety hazards.

The Hidden Dangers Beneath the Surface

Modern slabs often feature a complex system of embedded components. Within and below the slab you may encounter:

Electrical Conduits

Plumbing Lines

Coring or drilling into any of these components have serious consequences. Striking a post tension cable can release stored energy with violent force that endangers crews and can reduce structural reliability. Damaging electrical conduits can cause outages, fire, or electrocutions. Drilling into a plumbing line can flood work areas and halt production.

These events occur on jobsites worldwide and lead to extra costs, schedule impacts, and risks to workers on site.

Why You Need to Know What’s Below

Before coring, you need field-verified information about what is inside and below the slab.

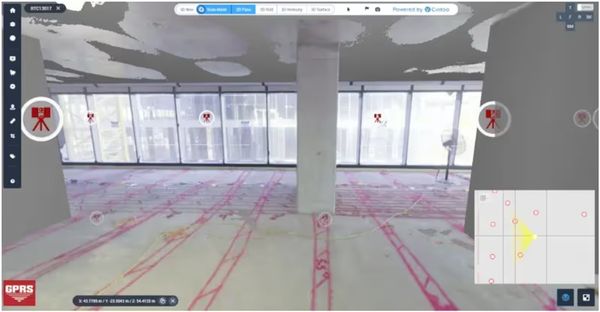

Ground penetrating radar (GPR) is a non-destructive imaging method that is used to locate and map embedded elements in concrete slabs. A GPR scanner emits radio waves into the slab. The device measures interactions between those radio waves and objects such as rebar, post tension cable, and conduit. On a GPR readout, interactions typically appear as hyperbolas whose size and shape are determined by the material detected.

Unlike X-ray scanning, GPR requires access to only one side of the slab and introduces no radiation risk. It is fast, accurate, and well suited to identifying:

Rebar patterns and depth

Post-tension cables

Conduits and pipes

Likely voids or honeycombing

Embedded anomalies

When a qualified concrete scanning professional interprets the data, clearly marked safe coring locations are established. This ensures coring can continue while avoiding critical embedded infrastructure and complying with project safety requirements.

Let GPRS Keep You Safe When You Need to Core

Concrete coring is a precise task with real risk, not just drilling holes. Since slabs often contain complex reinforcement and utilities, every coring operation should be guided by accurate, actionable data.

Without data verified by professional concrete scanners, the chance of job site injuries and financial setbacks increase significantly.

GPRS delivers precision concrete scanning services that help keep concrete coring projects on time, on budget, and safe. Using GPR scanning, electromagnetic (EM) locating, and other complementary technologies, we Visualize The Built World® so you can plan and dig with confidence. Our SIM-certified Project Managers have maintained a 99.8% accuracy rate when scanning concrete, providing industry-leading results to help you work efficiently while avoiding strikes and delays.

Concrete Thickness

GPRS Project Managers provide GPR scanning services to capture key slab information for structural engineers. This information includes concrete cover and overlay thickness, concrete thickness, and dowel placement. GPRS is equipped to evaluate projects of any size or scope.

Slab On Grade

A major advantage of GPR over X-ray is its ability to scan slab-on-grade. GPR only needs access from a single surface, so it can locate embedded conduit and other anomalies inside the slab.

Shallow Utility Locating

For slab-on-grade, the risk extends below the concrete. GPRS Project Managers use GPR and EM locating to deliver a 99.8% accurate picture of utilities within and beneath the slab.

Conduit Mapping

Severing electrical conduit creates safety hazards and expensive downtime. We mark GPR findings directly on the slab to show where subsurface obstructions are present and where it is safe to cut or core.

Rebar Locating

Damaging rebar will cost tens of thousands of dollars, and that’s not even including any structural damage or injuries that follow. GPRS Project Managers are trained to use GPR to locate and map rebar within concrete.

Post Tension Cable Mapping

Our concrete scanning services can locate post tension cables prior to drilling. Our findings are marked on the surface, and we can produce 2D CAD drawings and a 3D BIM model that depicts the cable layout.

The GPRS Green Box Guarantee

When GPRS places a Green Box within a slab layout before you cut or core, we guarantee that area will be free of obstruction.

If we’re wrong, we agree to pay the material cost of the damage.

The Green Box Guarantee details is presented directly on the surface of the coring location to remove ambiguity about where you can and cannot core. GPRS Project Managers also conduct a post-job walkthrough to review all Green Box locations.

Post Tension Slab 3D BIM Modeling

See inside your post-tensioned concrete slabs. This isn’t limited to only PT cables. The models also include conduit, cable draping, and rebar. Comprehensive 3D BIM models help you avoid damages while also planning and building better.

Case Study: GPRS Provides Accurate PT Cable Layout for 49-story Building

Task:

GPRS partnered with Turner Construction to locate and mark the complete post tension cable system for floors 12-23 of a 49-story project, covering approximately 12,500 square feet per floor. After scanning each floor with GPR, each floor was also scanned with our LiDAR-based 3D laser scanners. The data produced enabled our team to produce 2D CAD drawings and a 3D BIM model for virtual design and construction. This provided the architect with a permanent record of the PT layout to complete fit and finish plans for the 12 floors.

Problem:

The AEC team required precise interior PT slab mapping to support design, planning, and construction on a mixed-use building. Each PT cable carries up to 30,000 lbs of load and costs $20,000 to $30,000 to replace.

Solution:

GPRS Project Managers used GPR to scan the interior of each slab, then captured surface markings with 3D laser scanning. Our in-house Mapping & Modeling Team used the combined data to create accurate 2D CAD drawings and a 3D BIM model of each slab interior, including individual and bundled cable drape.

The Bottom Line:

Frequently Asked Questions

How is GPR used to identify tendons vs. rebar in a post-tensioned slab?

In post-tensioned structures, we typically find one mat of support rebar near the base of the slab. This mat is generally consistently spaced and remains at a constant elevation. Post-tension cables are generally found above this support mat and “draped” throughout the rest of the structure. The elevation of the cable is usually high near the beams and column lines and drapes lower through the span between beams and column lines. Knowledge of these structural differences allows us to accurately differentiate between components. Our Project Managers will leave you feeling confident in our findings and in your ability to drill or cut without issue.

How long does it take to scan an area for core drilling?

GPR is an extremely efficient and rapid technology. Large areas can be easily and quickly scanned with the state-of-the-art GPR units utilized by GPRS Project Managers. Our standard layout for a typical core drilling location is 2’x2’. It usually takes about 10 minutes to scan and mark an area this size.