GPRS Reality Capture Services Accelerate Hydroelectric Dam Renovation

Because no accurate documentation of the buildings existed, the team needed a complete picture of the interior layout. Every pipe, transformer, and structural element had to be mapped to guide the renovation process.

GPRS Project Manager, Dean Sturt on location in the Arizona desert with his 3D LiDAR laser scanner.

Private Utility Locating Company Highlights Its Reality Capture Services

To support planned upgrades at a hydroelectric dam approaching its 100th year of operation, GPRS Reality Capture Services provided detailed, reliable data that helped the project team move forward with confidence. Dean Sturt, a GPRS Project Manager, was assigned to scan the dam’s two powerhouses using advanced 3D laser scanning technology.

Located at the base of the dam, the powerhouses are multi-story structures filled with tightly packed mechanical and electrical systems. Because no accurate documentation of the buildings existed, the team needed a complete picture of the interior layout. Every pipe, transformer, and structural element had to be mapped to guide the renovation process.

“Accurate, real-time as-built data is essential for informed decision-making and seamless collaboration,” said Sturt. “With precise design plans from the start, architects, contractors, engineers, and facilities managers can streamline fieldwork and minimize change orders, plus avoid delays and extra costs.”

GPRS uses Leica laser scanners to produce high-resolution point clouds, 2D CAD drawings, and 3D BIM models. These deliverables give stakeholders a clear view of existing conditions and help them plan more effectively.

Before scanning began, Sturt spent several hours walking the site with the dam’s operations team. “We walked it top-to-bottom, the whole facility, just so that I could mentally game plan where to start, how many floors there were, etc.,” he said. “They didn’t have any plans of the facility to start from, so it wasn’t like going into it I already had a base to go off. So, I walked it with those guys, asked a lot of questions.”

GPRS scanned powerhouses, nearby structures, and the areas surrounding the dam to provide accurate existing conditions documentation to the engineers.

Over the course of several days, Sturt scanned every section of the powerhouses and nearby structures. “It was a little daunting at first, just those dense areas, a lot going on in kind of a small space,” he said. “But as you start going through it, it made a lot more sense.”

The scan data was then handed off to GPRS’ Mapping & Modeling Team, who used it to create:

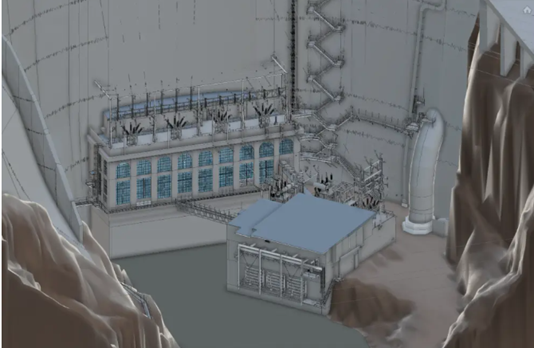

A full 3D model of both powerhouses

A virtual walkthrough and 2D floor plans of the dam’s infrastructure

Senior Modeling Technician Nate Nowels described the modeling process. “[The customer] wanted a full 3D model of both powerhouses, so the additional topography and the rest of the dam [shown in the deliverables] is pretty much just for reference,” he said. “We were responsible for modeling all the equipment structural components, and all the architectural features… It was structural beams, columns, trusses, all the architectural elements, and then into the mechanical systems. So, ducts, the footprints of actual equipment, we got pipes and all that kind of stuff, valves, actuators, everything… All the mechanical items were captured.”

GPRS Senior Modeling Technician, Nate Nowels

Modeling the mechanical systems came with its own set of challenges. “There were pieces of equipment that ran through multiple floors,” Nowels explained. “With a lot of factories, you’ll have some equipment that runs from, say, level one to level two. But in powerhouse two, for example, there’s a turbine that runs all the way down into the water and then up through multiple layers. It’s a very unique object to model; it has lots of mechanical piping going in and out of it.”

He added, “It’s multiple levels of a piece of equipment running through multiple floors… You wouldn’t want your entry level engineer or designer on it. You need to have extensive knowledge of the [modeling] software, for sure.”

One of the group of deliverables crafted by GPRS Mapping & Modeling for the dam upgrade project. A 3D Model, WalkThru 3D virtual tour, and 2D Floor plans were all part of the deliverables package.

Thanks to GPRS’ Reality Capture Services, the client now has a dependable record of the dam’s current conditions. “They have nice existing condition documentation of [this equipment on] the day that we scanned it,” Nowels said. “And they’re able to tie into all the mechanical systems, HVAC systems, and add on however they need to add on.”

Although it wasn’t required on this particular job, GPRS has mastered the practice of converting 2D utility and concrete markings into accurate 3D objects, like models, and digital twins to help architects, engineers, and general contractors plan, build, and manage better. All GPRS deliverables are accessible to customers via the SiteMap platform, where teams can collaborate & communicate to keep projects on time, on budget, and safe.

It's yet another way GPRS is Visualizing The Built World® for our customers.

What can we help you visualize?

Frequently Asked Questions

1. Why was reality capture essential for this hydroelectric dam project?

The dam lacked accurate existing documentation, making it difficult to plan upgrades. GPRS used 3D laser scanning to capture precise as-built data, enabling engineers and contractors to design confidently, reduce field time, and avoid costly changes during construction.

2. What types of deliverables did GPRS provide?

GPRS delivered a full 3D model of both powerhouses, 2D floor plans, and a virtual walkthrough. These tools gave the client a clear view of existing conditions and supported efficient planning and collaboration.

3. What challenges did the modeling team encounter?

Modeling complex mechanical systems that spanned multiple floors was a key challenge. Equipment like turbines required advanced software knowledge to accurately represent their structure and connections across several levels.