Leaking underground storage tanks pose significant risks to property owners. We explain how we find them and map them to help mitigate brownfield risk.

Explaining USTs and LUST sites

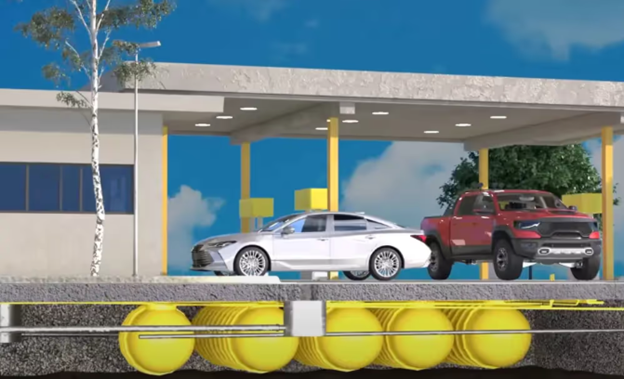

Underground Storage Tanks (USTs) are widely used for storing petroleum and hazardous substances at gas stations, industrial sites, and commercial properties. However, improper installation, aging infrastructure, or lack of maintenance can lead to leaks, resulting in significant environmental and regulatory concerns.

Underground storage tanks are crucial components of various industries, especially in downstream petroleum production, and hazardous chemical storage. Deterioration or improper management of these tanks can cause critical leaks that pose extreme environmental risks.

What Are Underground Storage Tanks (USTs)?

USTs consist of underground tanks and piping systems designed for fuel storage. They must meet strict regulatory requirements to minimize the risk of leaks and contamination. These tanks are commonly found at fueling stations, brownfield sites, and commercial properties with storage needs.

Key Components of UST Systems

- Tanks – Typically made of steel, fiberglass, or composite materials

- Piping Systems – Connect storage tanks to dispensing units

- Leak Detection Systems – Monitors that detect fuel seepage

- Cathodic Protection – Corrosion prevention for metal tanks

- Overfill Protection – Prevents spills during fuel transfer

Modern USTs are built to high safety standards, but older tanks—particularly those installed before stringent environmental regulations—are vulnerable to corrosion, structural failure, and leaks.

USTs and their piping infrastructure are often used to store petroleum products like gasoline and other hazardous materials.

What Are Leaking Underground Storage Tanks (LUSTs)?

LUSTs occur when underground tanks deteriorate, crack, or fail due to mechanical issues. These leaks can release hazardous substances into soil and groundwater, posing environmental and financial risks.

Common Causes of LUSTs

- Corrosion – Rusting of older steel tanks leading to breaches

- Structural Failure – Pressure shifts and environmental stressors causing deterioration

- Improper Installation – Faulty setup contributing to early failure

- Accidental Damage – Excavation or construction impacts rupturing tanks or piping

- Neglected Maintenance – Lack of routine inspection increasing risk of leaks

Environmental and Health Risks of LUSTs

Leaking USTs pose substantial threats to human health and the environment, including:

- Soil Contamination – Hazardous chemicals seep into the ground, affecting vegetation and ecosystems

- Groundwater Pollution – Substances such as benzene, toluene, and MTBE infiltrate water supplies

- Air Quality Issues – Volatile organic compounds (VOCs) from fuel leaks cause inhalation hazards

- Fire and Explosion Hazards – Underground fuel leaks create flammable vapor pockets

- Legal and Financial Liabilities – Property owners face regulatory fines, lawsuits, and remediation expenses

Regulatory Framework for USTs and LUSTs

USTs in the United States are regulated under the Environmental Protection Agency’s (EPA) Resource Conservation and Recovery Act (RCRA). These regulations mandate:

- Tank Registration & Monitoring – All USTs must be registered, with owners responsible for implementing leak detection systems

- Operator Training & Inspection – Routine inspections and compliance training are required

- Corrective Action for Contaminated Sites – Cleanup operations must adhere to EPA and state guidelines

- Closure & Removal Requirements – Decommissioning must follow specific environmental procedures

Detection and Remediation of LUST Sites

Environmental consultants conduct site assessments when a LUST is suspected to determine contamination severity. The remediation process includes:

- Phase I Environmental Site Assessment (ESA) – Identifies Recognized Environmental Conditions (RECs) via historical records and visual inspections

- Phase II ESA – Includes soil, groundwater, and air sampling to confirm contamination levels

- Site Remediation Strategies:

- Soil Excavation & Disposal – Removing contaminated soil

- Groundwater Treatment – Pumping and treating polluted water

- Vapor Intrusion Mitigation – Installing barriers to prevent indoor air contamination

- Bioremediation – Utilizing bacteria to break down pollutants

How GPRS Supports LUST Detection and Remediation